Stephen Gould is ready to help you choose the right automotive packaging solution for your product specifications and budget. Our team has extensive experience working with Tier 1 North American suppliers who trust us to safeguard crucial parts and products during transportation and storage.

Car and Automotive Manufacturing has long been one of the largest manufacturing industries in the world. Six of the ten largest manufacturing companies in the world when measured by revenue are automakers.

Vehicle assembly is a complex process requiring thousands of parts and components, from the engine to small mechanical pieces. The automotive industry understands the crucial importance of investing in industrial packaging solutions to keep auto parts safe en route from suppliers. Stephen Gould creates custom automotive packaging and shipping solutions that protect auto parts and minimize costs.

Types of Automotive Packaging

There are two primary types of packaging used by automotive manufacturers: expendable and returnable.

Expendable Packages

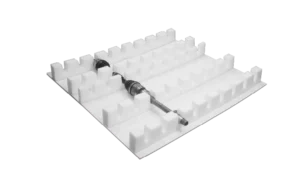

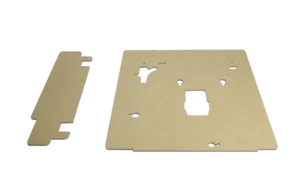

Expendable or single-use, packages are made from materials such as paper, foam, wood or corrugated cardboard. Expendable packages are typically recycled or disposed of after the product has reached its destination. The disposal process for expendable packages is incorporated into the lifecycle of the manufacturing and packaging process.

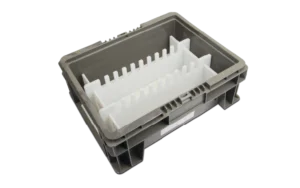

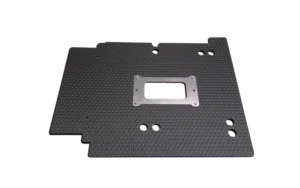

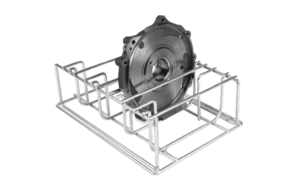

Returnable Packages

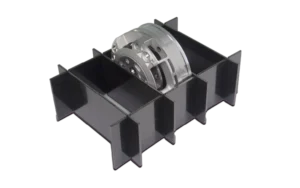

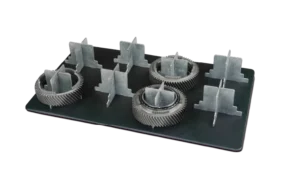

Returnable packages are designed to be reused in manufacturing and distribution systems. Types of returnable packaging includes racks, pallets, crates, dunnage, and hand-held containers. Not only does returnable packaging cut down on excess packaging waste, it provides enhanced protection. The rigid materials used to make returnable packaging also tend to provide better moisture and contaminant protection during transit. Reusable packages are also easier to track with an inventory control system.