Team

Capabilities

Demonstrating Excellence

All WorkWe worked closely with Benjamin Moore to completely reimagine the demo board kits used by their sales team to demonstrate their products. Our team spearheaded every phase of this project, from design, to manufacturing, to distribution, creating a full turn-key solution.

The Challenge

Alex Schoenfeld, from our Rye Brook, NY location, had previously produced Benjamin Moore’s paint swatch binders. Knowing Stephen Gould’s track record for quality manufacturing and attention to detail, Benjamin Moore asked Alex and his team to redesign the demo board kit that their sales team uses to showcase products.

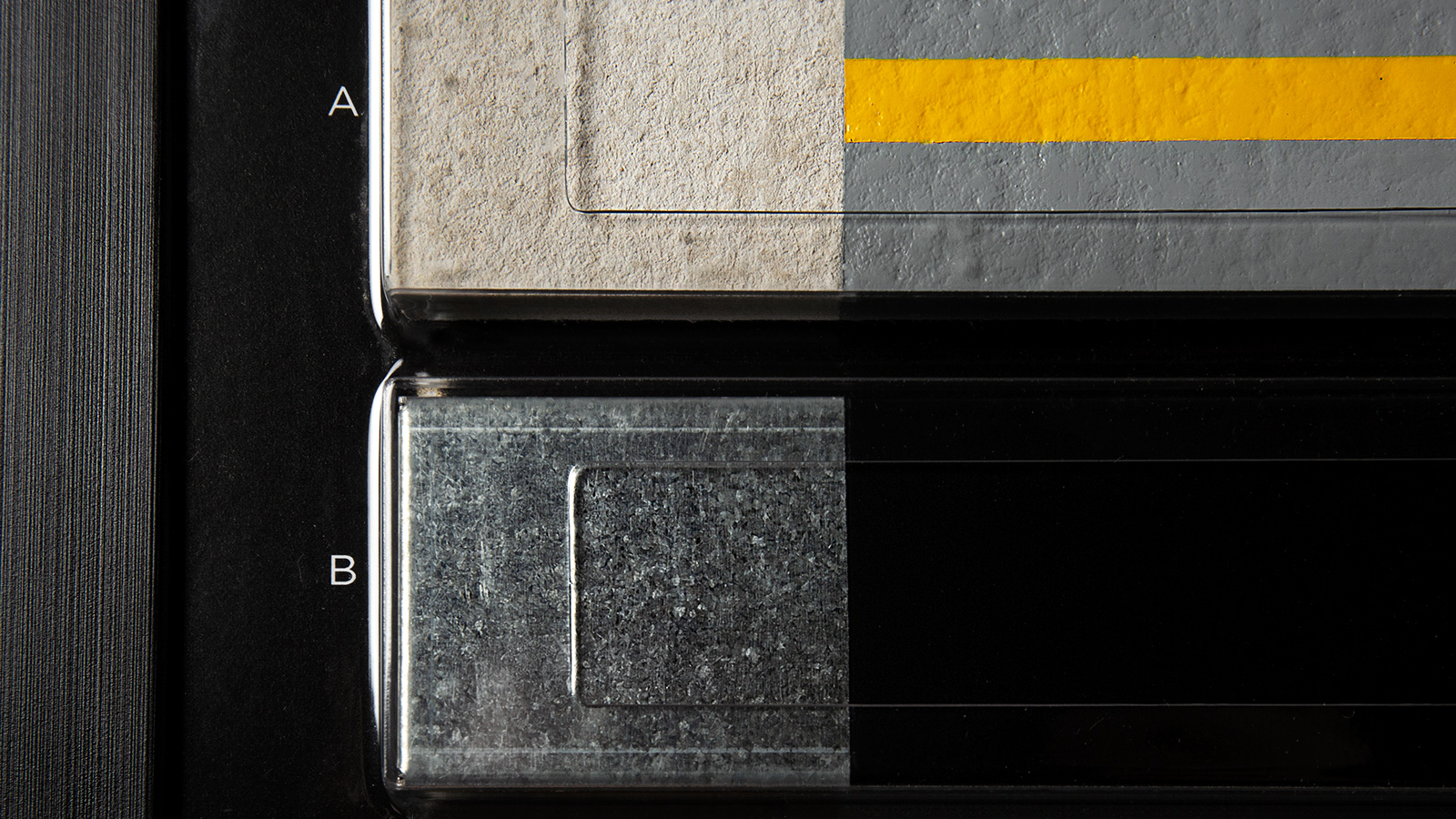

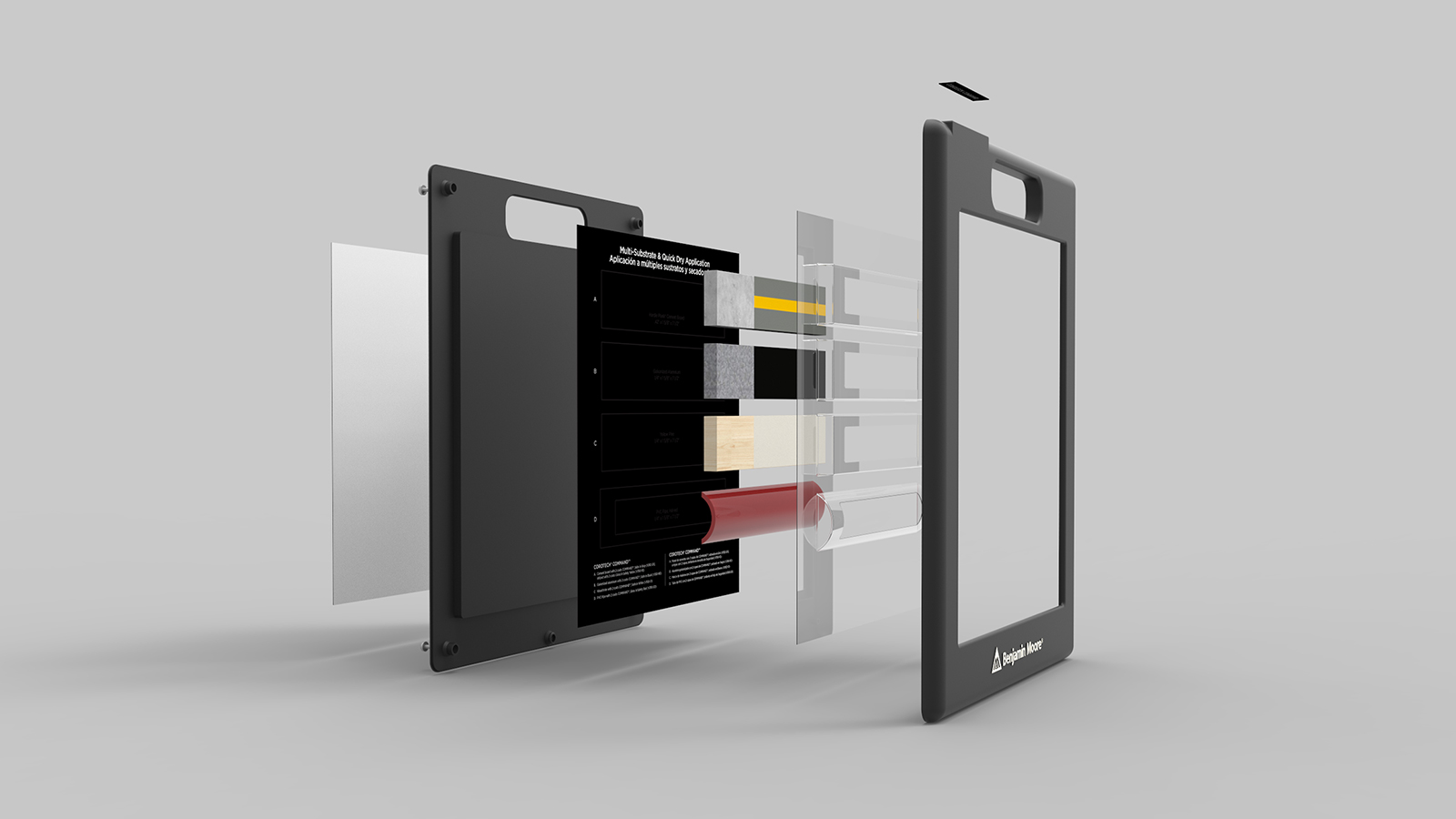

The kit included up to eight boards and required a custom luggage carrier for easy travel. Each board demonstrates a paint or primer coating applied to various surfaces found in a typical house: pine, cedar shake, drywall, aluminum, tile, and close to twenty more. The presentation allows sales reps to communicate the benefits of each respective SKU and compare alongside their competitors.

Creating the kits called upon the full strength of our manufacturing, quality assurance, and project management expertise. The Madison team needed to procure a wide range of materials from multiple suppliers and coordinate multiple departments within Benjamin Moore. A complete kit would require several layers of manufacturing, including print, thermoforming, injection molding and wood/metal substrate painting. After experiencing quality control issues with their previous supplier, it was also important to develop a robust quality management system that gave the client full visibility into the production process.

The Solution

The key to this project’s success was the close, collaborative partnership that the Madison team developed with the client. Clear communication and trust were especially important during the many rounds of iterating and problem solving throughout the project. Members of the Madison team were in Benjamin Moore’s office every week to review progress and drive the project forward.

The Madison team started by examining the areas where the previous supplier was falling short and developing new approaches. After cleaning up those issues, they produced a pilot test of 150 cases for a group of outside sales reps to test in the field. The injection mold and thermoform pieces were redesigned to improve the overall quality.

The trickiest problem to solve involved the painted substrates. Benjamin Moore asked the them to develop a process for spray painting rather than hand painting, the materials. Spray painting would achieve greater cost savings. The problem is that oil-based paints are highly flammable and many states, such as New Jersey, have tight regulations on facilities for paint spraying. After a good amount of research, the Madison team was able to locate a facility in Philadelphia that could do all the spray painting, including the oil-based paints, under one roof.

Once the design was finalized and the supply chain was in place, the Madison team began to implement a rigorous quality management system (QMS) across all aspects of production and fulfillment, including print, thermoforming, injection molding, kitting, and distribution. Throughout the entire process, they invited the client to meet suppliers and visit the production plant. This helped them gain a deeper understanding of how the boards were board and what was feasible from a manufacturing standpoint.

The Result

Our team delivered a brand new supply chain built from the ground up. Every aspect of manufacturing, quality assurance, and distribution is overseen and executed by Stephen Gould. The new demo boards are currently being rolled out and distributed to sales reps.

This project required deep understanding of the client’s business, from the needs of their sales reps to the nuances of several product lines. As we learned more about how Benjamin Moore worked, we were able to bring people together across departments and create new systems that fast-tracked approvals and opened up new lines of communication.

Get in touch

Questions? Let’s talk. Our team can help you find what you're looking for.