Positively Visionary

All WorkStephen Gould team members created and patented Positive Fusion, a revolutionary asset-tracking software/hardware solution. Initially developed as a tool control system for aviation maintenance, Positive Fusion is proving to have an array of practical applications across dozens of industries.

The Challenge

One of the aviation industry’s costliest problems is damage sustained by aircraft in flight from birds, hail, ash, and other objects. Boeing estimates that Foreign Object Damage (FOD) costs the industry around $4 billion dollars annually, a significant percentage of overall revenue.

The most preventable type of FOD is caused by tools left behind in the aircraft after servicing. Forgotten tools left in the engine, cockpit, and elsewhere can damage moving parts, cause electrical shorts, and jeopardize the safety of everyone on board.

FAA guidelines mandate all aerospace facilities must have a tool control program to combat Tool FOD. Asset tracking systems, employing Radio Frequency Identification (RFID), have been utilized to assist the industry with this onerous responsibility. RFID is the same technology found in employee badges that grant access to offices. By applying a RFID tag to a tool, companies greatly enhance overall visibility to the tool’s whereabouts. In addition to increased oversight, these systems also substantially improve efficiencies in procedures.

But there is no one-size-fits-all tool control system. Every company has its own custom, sometimes patchwork, system to address the operational and financial concerns of management as well as the practical needs of technicians. Aligning hundreds of employees to a new system is challenging and requires significant upfront investment.

Team members from Gould Southern, a subsidiary of Stephen Gould, saw the need for a more dynamic tool control system that would be easier and more affordable to implement. They set out to build a software/hardware solution that can bring together multiple tracking technologies within a single software environment and integrate with existing applications if needed. The solution that emerged is Positive Fusion.

The Solution

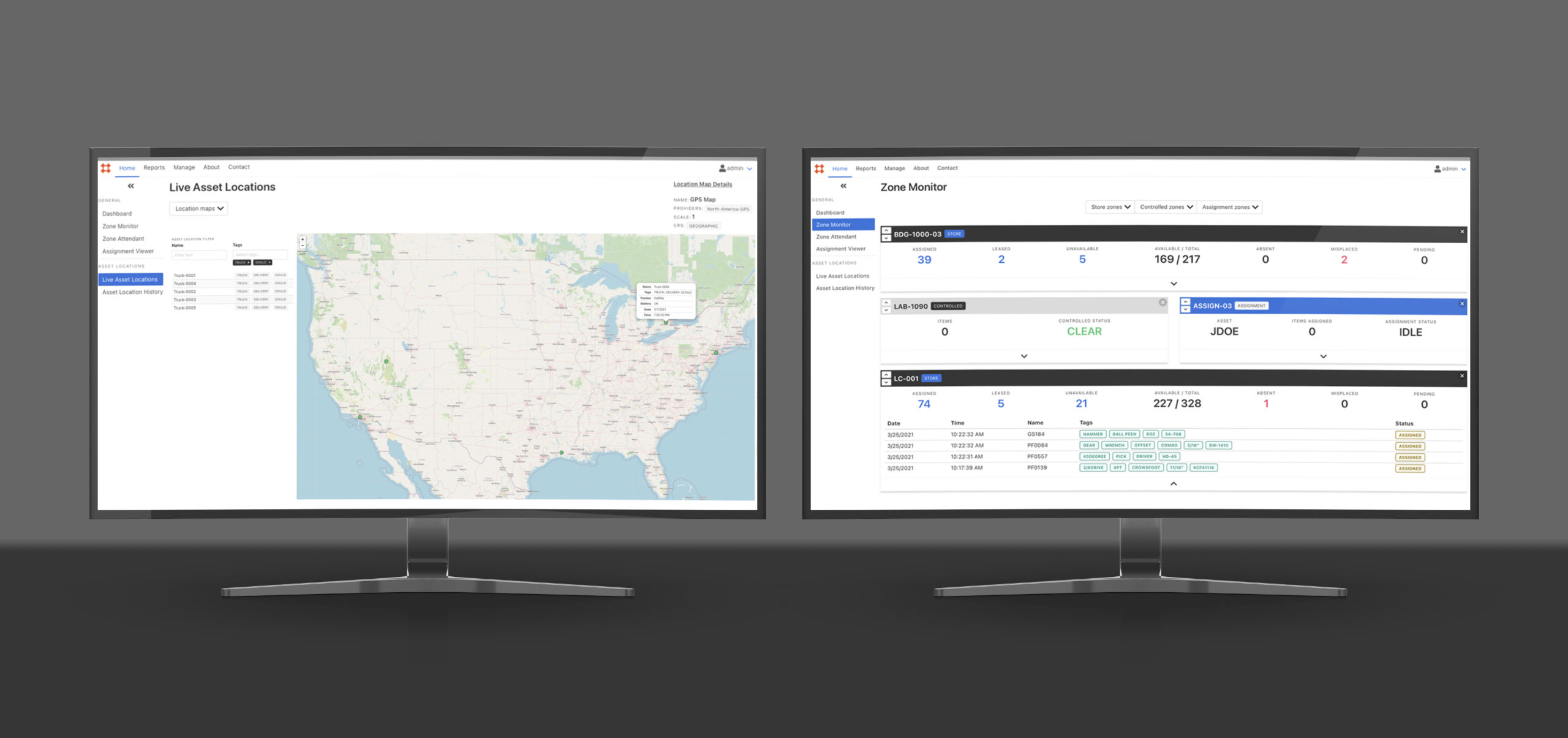

What sets Positive Fusion apart from other asset tracking solutions is its adaptability. Positive Fusion can work with a company’s existing systems and be gradually rolled out over time. It allows the use of multiple tracking technologies such as Passive RFID, Ultra-Wideband Technology (Active RFID), and GPS. From the start, it was clear that this flexibility gave Positive Fusion the potential for numerous commercial and industrial applications beyond aviation maintenance.

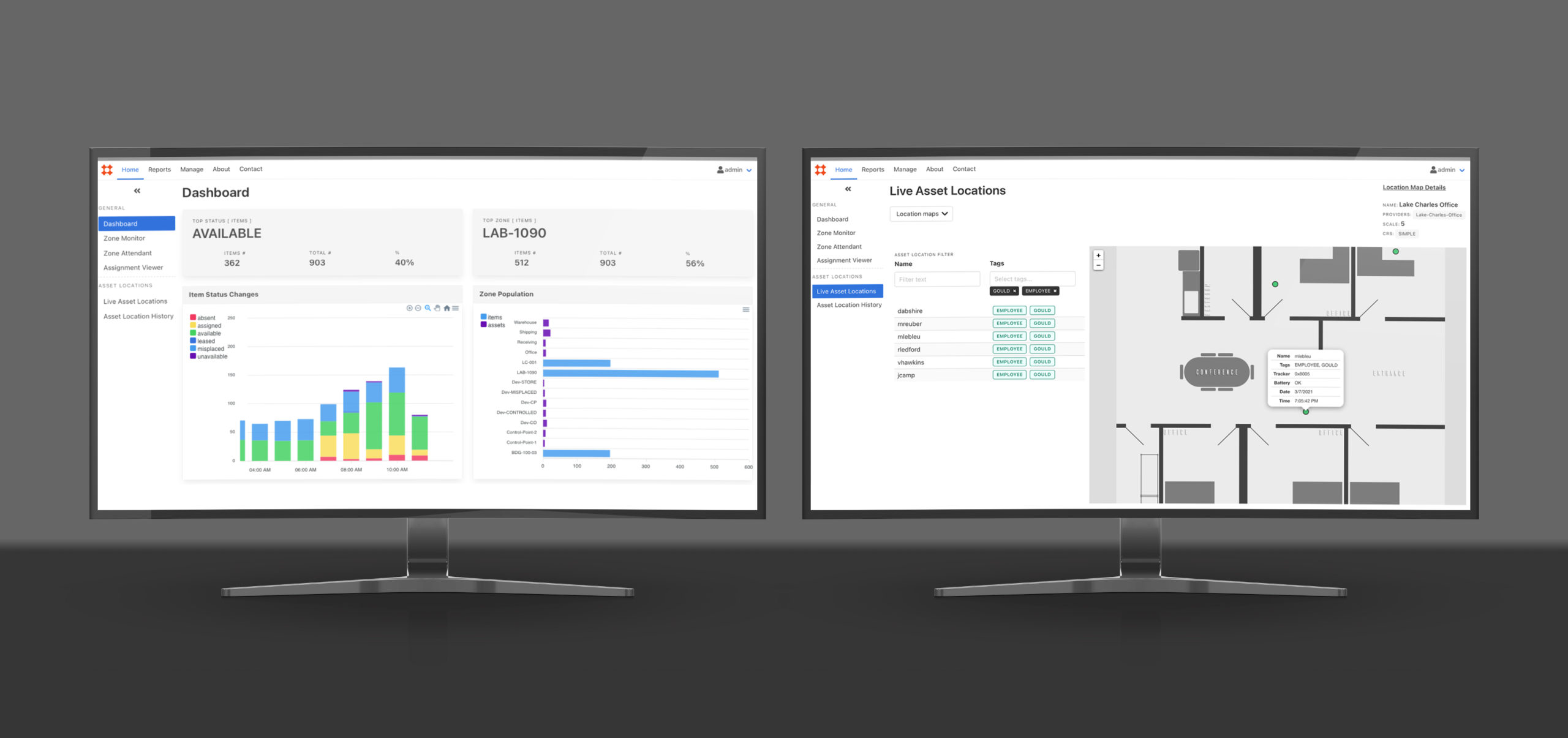

Positive Fusion’s software dashboards provide up-to-the-minute status and location of all assets and make several reports available to view any historical records. By increasing automation, the system minimizes human error that leads to lost assets.

Positive Fusion also dramatically streamlines the end-user experience by giving technicians the ability to instantly assign and return assets. With Positive Fusion, the assignment process does not require a technician to touch a computer and to return items. They just have to bring the tool(s) back to their designated “home zone”.

The first implementation of Positive Fusion was at an aerospace maintenance facility with nearly 200 technicians. The facility had an existing tool control system, but its limitations were apparent. Each hangar had one tool distribution area with a single-entry point, creating long lines and congestion. System data was often inaccurate and slow to update. Tools went missing for weeks without notice until there was a manual audit. All of this was costing the facility time and money.

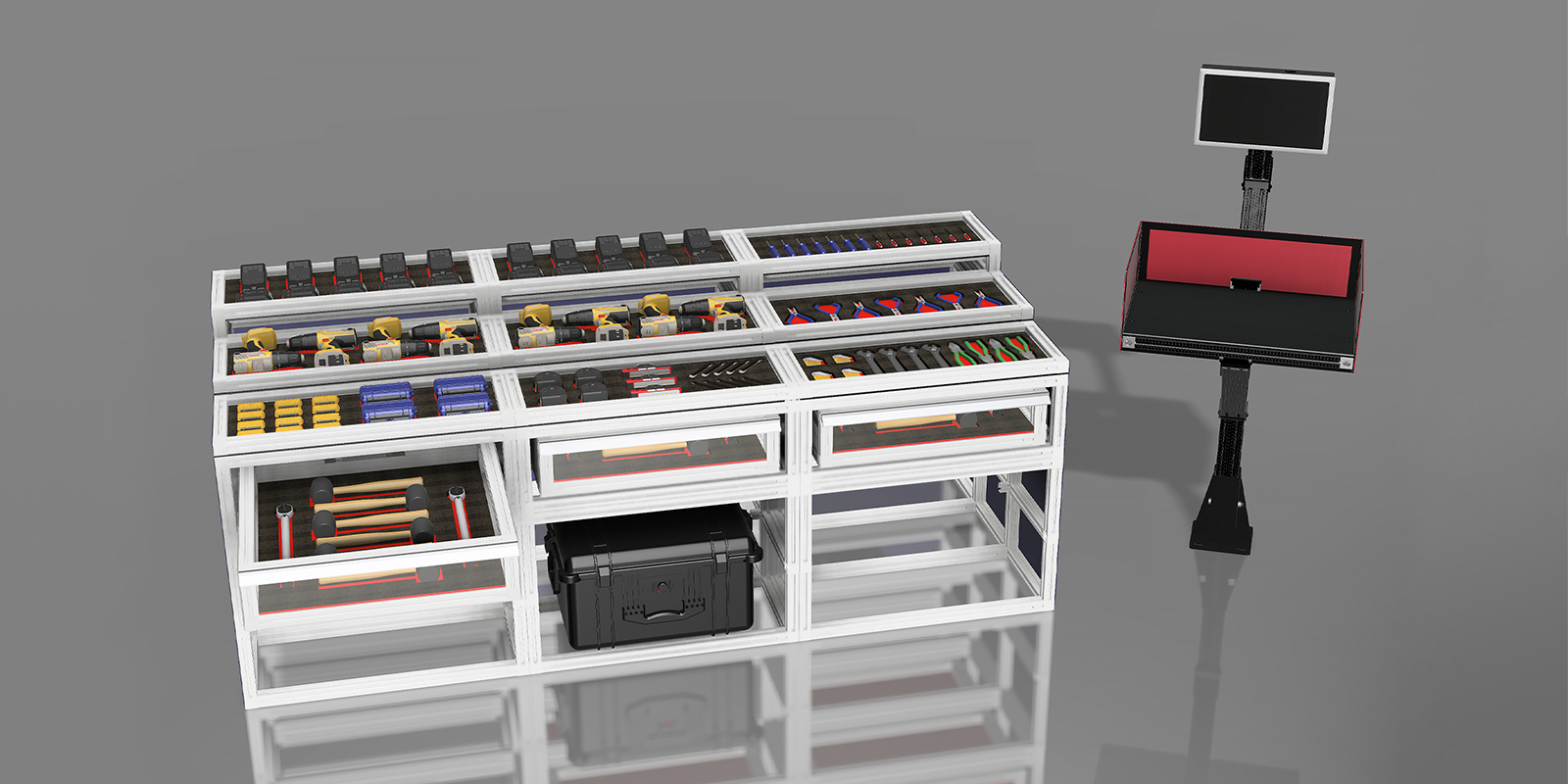

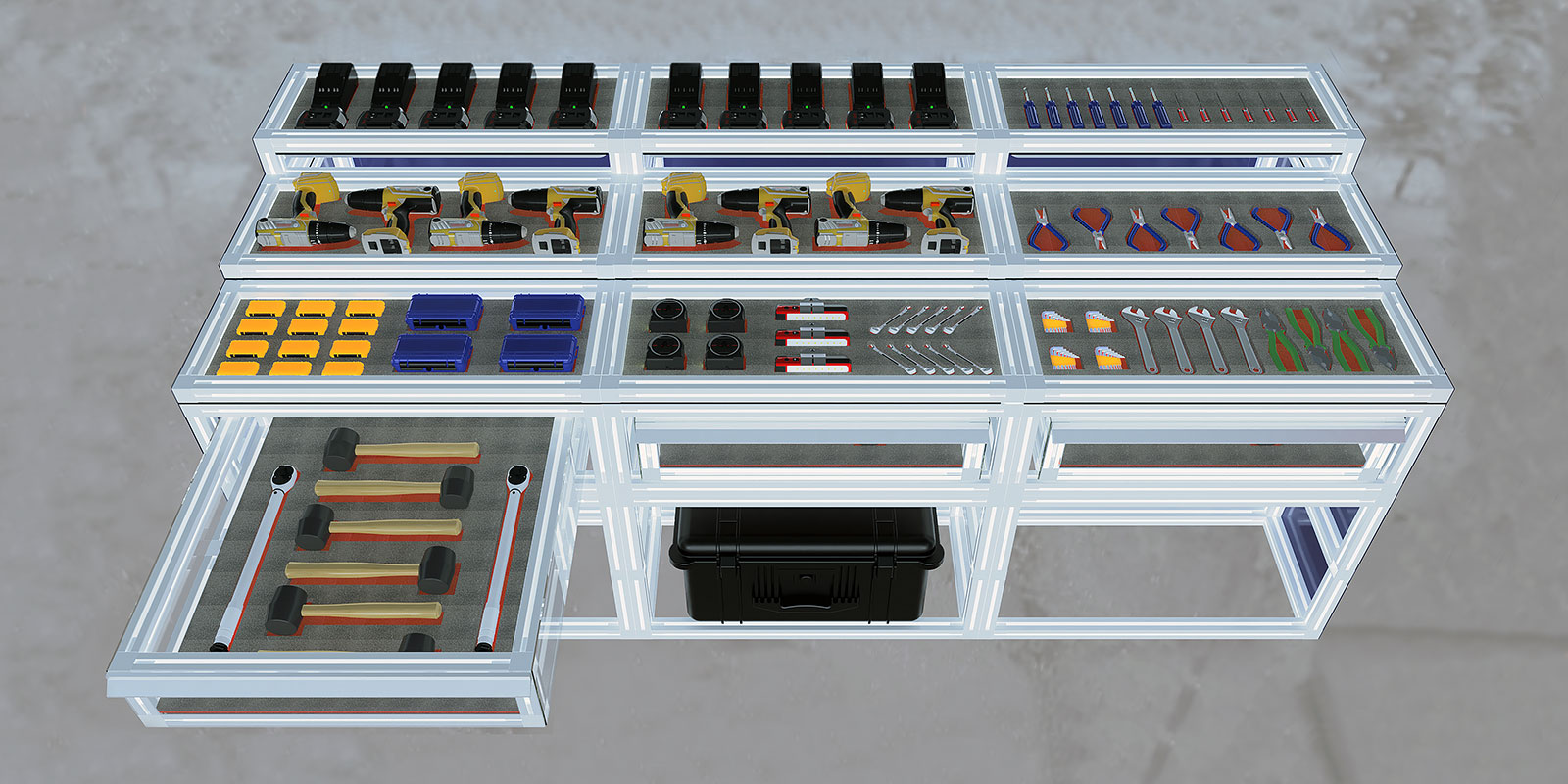

Stephen Gould resolved these issues by pairing Positive Fusion’s software with custom hardware tailored to the facility’s needs. The central distribution area was replaced with several “hot” tables for tool storage and distribution. Each table contains an RFID reader that constantly scans tools while they sit in their designated locations. Administrators now have instant insights into tool status and technicians can easily access tools. The mobile tables can be positioned next to aircraft during repairs, increasing efficiency and saving time.

The Result

Since Positive Fusion’s deployment at the facility, only one item has been lost, which the company concluded to be a user error. Overall tool assignment and return transaction times have dropped from thirty minutes per shift to just seven minutes. The estimated cost savings from these improvements have had a substantial impact on the facility’s bottom line.

Positive Fusion is a classic example of Stephen Gould’s entrepreneurial culture in action. Our team members’ ingenuity and foresight in solving a specific problem for a specific industry has led to a solution that is applicable across a wide range of industries, from automotive parts to food manufacturing. Stephen Gould team members are continuously improving Positive Fusion as it gains more widespread adoption.

Get in touch

Questions? Let’s talk. Our team can help you find what you're looking for.