Team

Capabilities

Positive Impact Downstream

All WorkWe partnered with Simms, a premium fishing equipment company, to modernize their packaging production, from design to manufacturing. As we developed a new, more efficient supply chain, we also built lasting friendships with our counterparts at Simms.

The Challenge

Simms is a pioneering brand in the world of fishing equipment, accessories and apparel. John Simms founded the company in 1980 after seeing a need for higher-quality waders than what was available. Today, the Montana-based company offers hundreds of high-performance products that are thoughtfully designed for the fishing and outdoor lifestyle.

Stephen Gould came alongside Simms during a period of expansion that exposed the fragmented and inefficient nature of their previous packaging supply chain. Packaging produced in different facilities would arrive on store shelves with noticeable differences from each other. Materials used in one facility would be thicker than others, and printed colors would be slightly off. As a result, the brand lacked cohesion. They asked our Addison, Texas team to overhaul their entire global packaging operation to improve consistency, quality, and the overall sustainability of their supply chain.

Adding to the challenge was the large number of Simms products and long list of suppliers and facilities manufacturing those products across multiple continents. Despite the wide range of product offerings, Simms is still a modestly-sized company, so any solution would need to find ways to affordably and efficiently producing lower quantities of packaging. It was a highly complex challenge, but our team was ready to wade in and get started.

The Solution

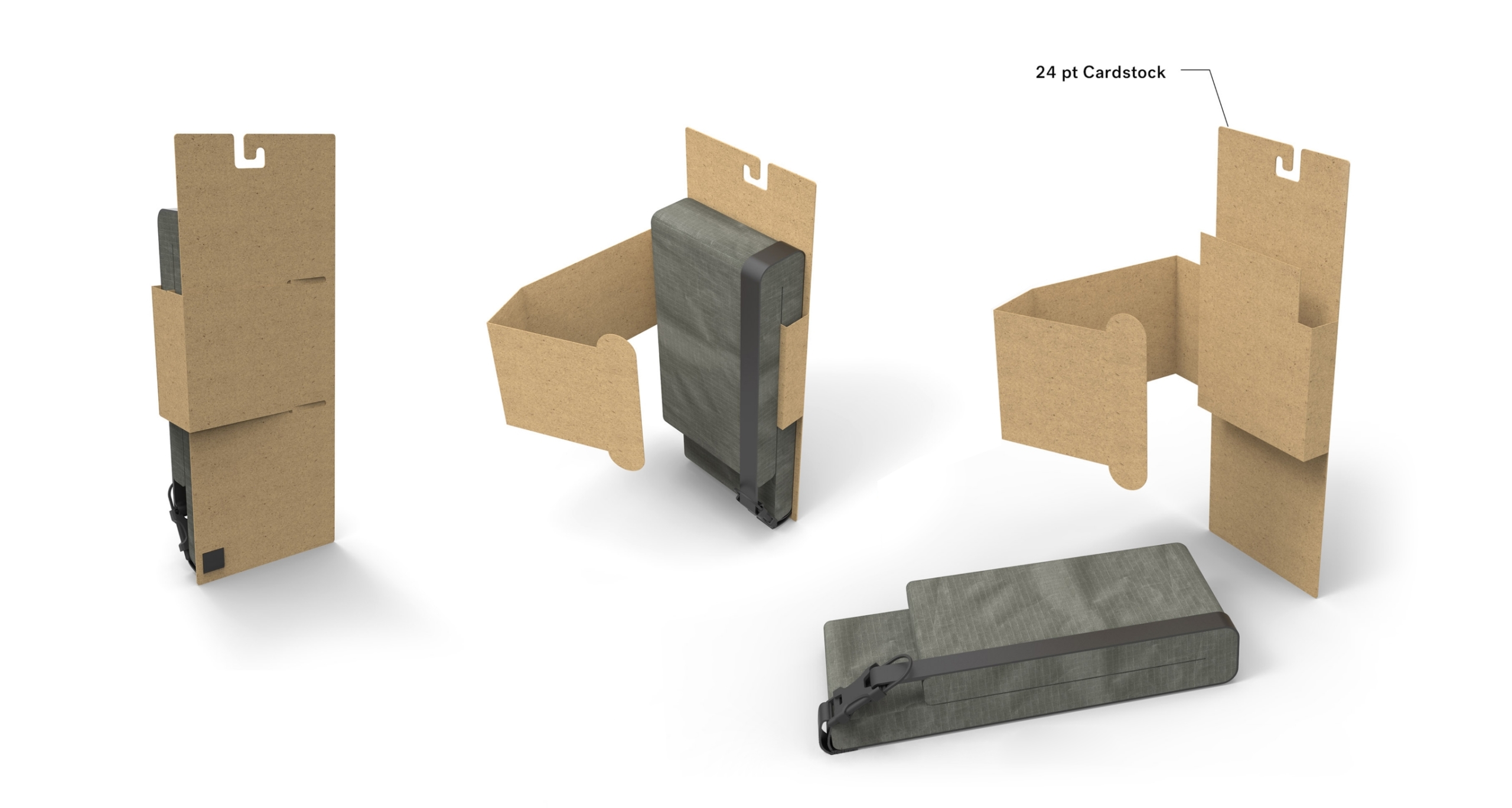

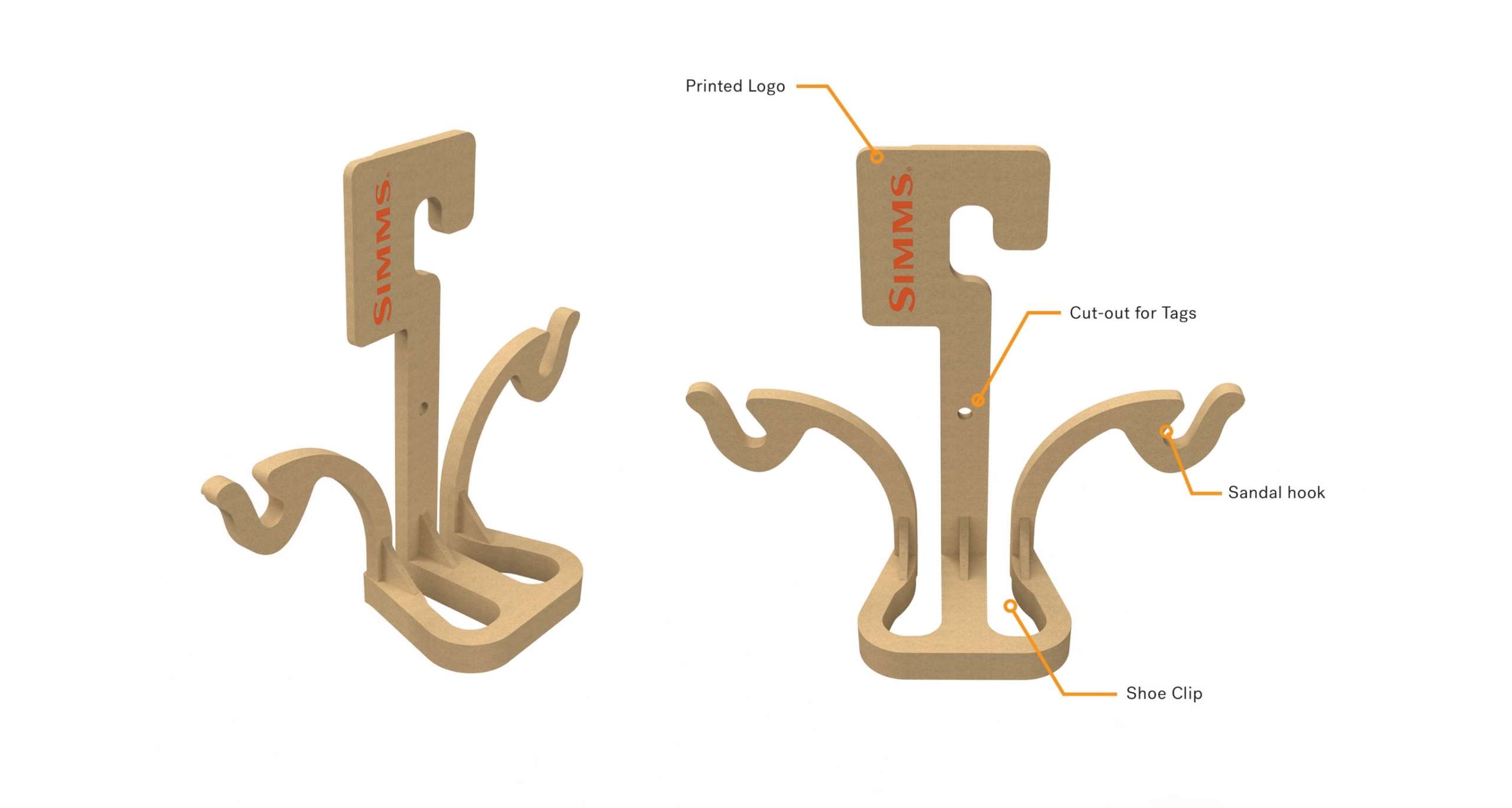

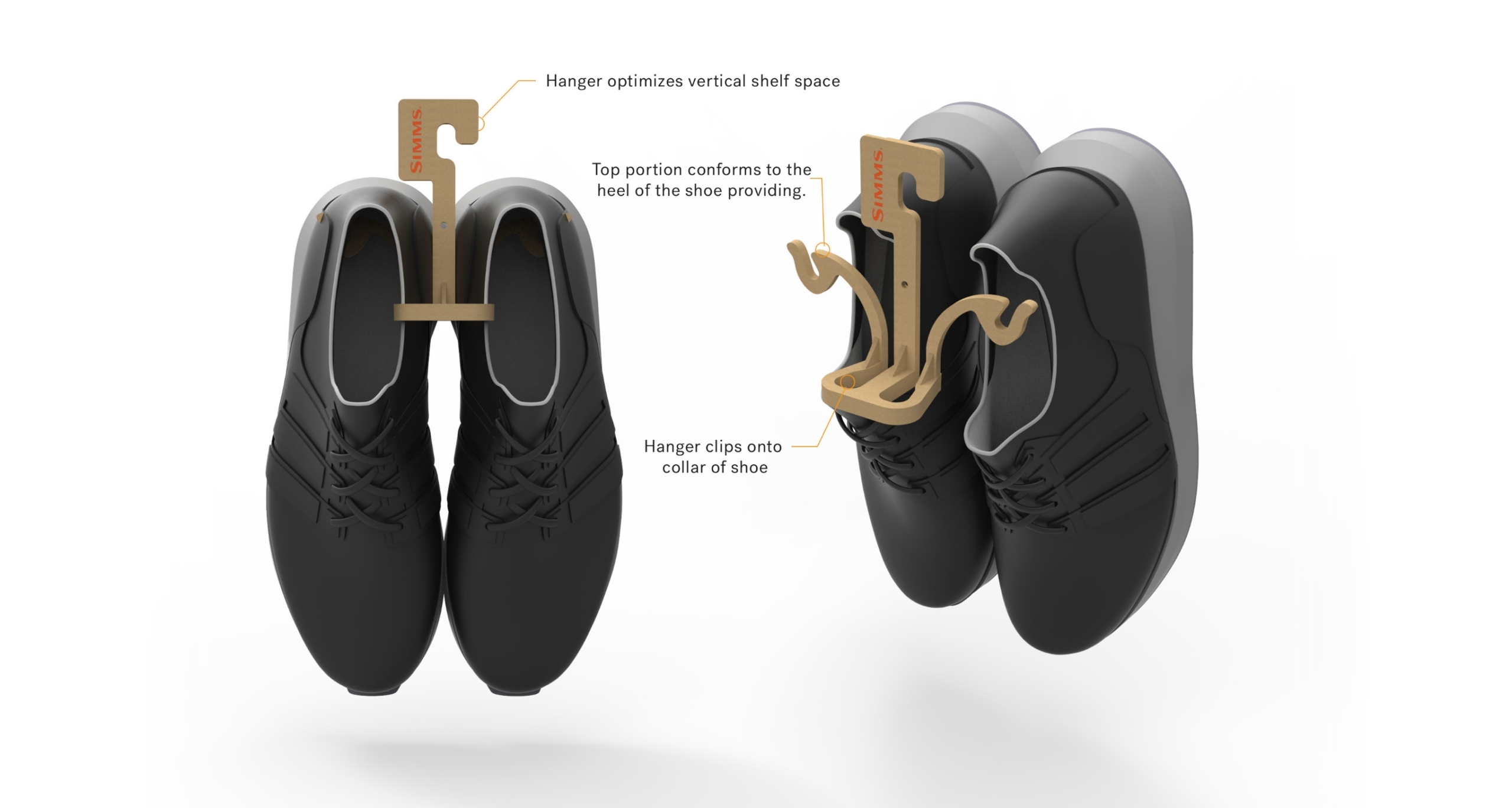

From the outset, it was clear that Simms’ goal was to be a product-first brand. Achieving that goal meant simplifying and reducing the amount of packaging so that the quality of the products would shine through. This was easier said than done with the sheer amount of parts and materials that went into the production of packaging for well over 100 SKUs. Our design team went to work streamlining all aspects of Simms’ packaging and creating guiding principles for greater consistency across the board. We also began to identify approaches and materials that would help Simms meet their sustainability goals.

The materials used in Simms’ packaging are relatively simple: corrugated boxes, folding cartons, polybags, and header cards. But manufacturing packaging for such a high number of SKUs at low volume in multiple facilities around the world created a high degree of operational complexity. Our team came up with a planning and production model that pre-builds inventory and distributes that across multiple suppliers over a mutually agreeable time frame. This made it possible to produce in quantities that support the relatively small volume needs within our supply chain.

Our team also worked overtime to source materials of similar quality and consistency in South America, Southeast Asia, and the United States. But just as we started getting the right pieces into place, the COVID-19 pandemic shut down production. Massive material shortages and shipping delays became the new normal. This had a huge impact on the new supply chain our team was building. In one instance, a production partner discontinued a board that had already been spec’d, tested, and validated. Our team scrambled to reallocate materials to another part of the globe and quickly test and validate the package again. Despite the last minute chaos, we adapted and still made the original launch date.

The Result

We successfully implemented a new planning and production model that allows Simms to efficiently produce all their packaging at the desired quantities with competitive costing. The revamped packaging line is clean, elegant, and set up well for continuous improvement and future iteration. Most importantly, the packaging reflects the elite craftsmanship of the products and creates a polished and consistent brand presence.

The key to the success of this project was the relationship we built with our counterparts at Simms. Things really could have gone south when so many unexpected disruptions hit during a particularly vulnerable moment in our supply chain’s development. But we had already laid a foundation of trust through countless meetings and a commitment to open and honest conversation. So when adversity struck, it only strengthened our bond. We became one team, united by our shared values and a genuine friendship.

Get in touch

Questions? Let’s talk. Our team can help you find what you're looking for.