In the fast-moving world of packaging, manufacturing, and supply chain management, precision is everything. A single missing part or incorrect material can delay production, drive up costs, and damage customer trust. That’s why every successful project starts with a clear and accurate Bill of Materials (BOM).

What Is a Bill of Materials (BOM)?

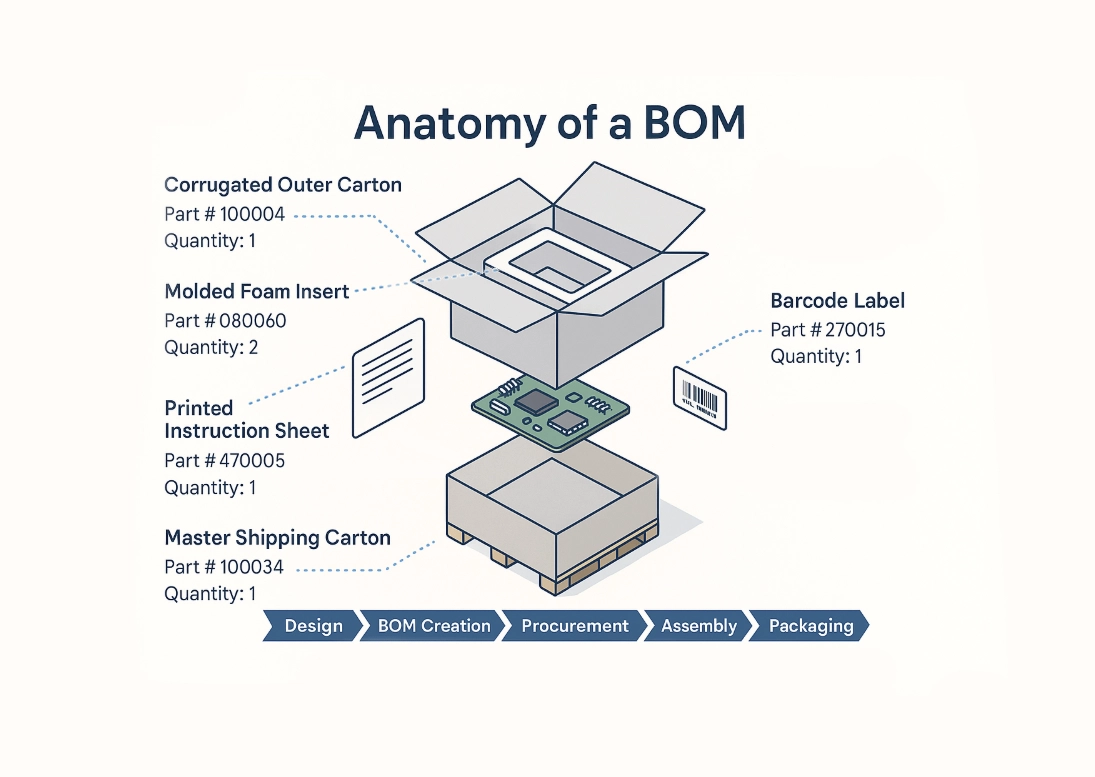

A Bill of Materials (BOM) is a comprehensive, itemized list of every raw material, component, subassembly, and packaging element required to build a product. Sometimes referred to as the blueprint for production, a BOM details:

- Material descriptions and part numbers

- Required quantities

- Specifications and sourcing details

- The hierarchy of how components fit together

For industries like automotive, electronics, consumer goods, and packaging, a well-structured BOM keeps design, engineering, procurement, and production teams aligned, ensuring that nothing is missed during the build.

Why a BOM Is So Important

A clear BOM is the backbone of efficient production. It helps companies:

- Prevent errors by ensuring the correct materials are ordered and used

- Control costs by reducing waste, rework, and over-purchasing

- Improve speed to market by streamlining the production schedule

- Maintain quality and consistency across multiple production runs

Without a BOM, companies risk miscommunication, costly delays, and quality issues that can disrupt the entire supply chain.

How Stephen Gould Supports BOM Development

At Stephen Gould, we help customers build complete lifecycle packaging programs that start with the right BOM.

By partnering with your design, engineering, and procurement teams, we:

- Audit your current BOMs to identify gaps or inefficiencies

- Recommend optimized materials, packaging formats, and sourcing strategies

- Develop production-ready specs that streamline procurement and reduce lead times

- Provide logistics and inventory support to ensure the right parts arrive at the right time

This holistic approach integrates design, supply chain, and manufacturing expertise, reducing risk while accelerating your speed to market.

Building for the Future

A well-built Bill of Materials helps your teams work smarter, not harder — and ensures your packaging and products move smoothly from concept to customer.

With more than 80 years of experience and a nationwide network of design centers, manufacturing partners, and distribution hubs, Stephen Gould delivers the clarity, precision, and operational support needed to keep your production lines running and your business moving forward.