Team

Capabilities

Precision in Motion

All WorkStephen Gould’s Tennessee office is a leading packaging company supporting the automotive industry across the Southeast, from Nashville to major manufacturing hubs. Our team partners with Tier 1 and Tier 2 automotive suppliers to design and deliver custom packaging solutions that protect components at every stage of production. From bulk racks for raw materials to work-in-progress containers for stamped panels and service packaging for aftermarket parts, each solution is engineered to fit the part, the production process, and the people handling it, ensuring efficiency, safety, and supply chain continuity.

The Challenge

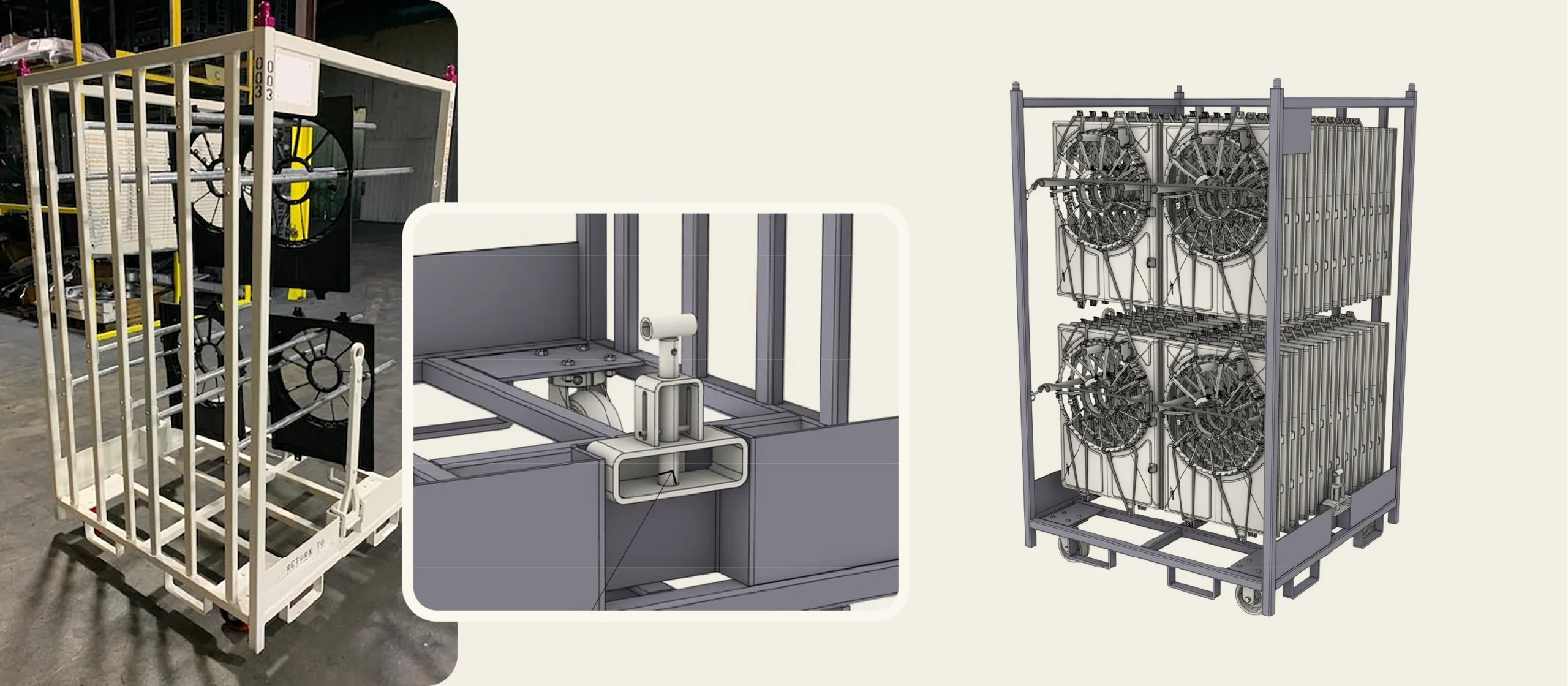

Automotive suppliers face strict production schedules while managing parts that constantly change in size, shape, and handling requirements, especially for major OEM brands like Honda and Nissan. Components may start as flat blanks and move through multiple processes, stamping, painting, machining, before reaching the OEM. Many Tier 1 and Tier 2 suppliers require multiple packaging systems for a single part and need a trusted automotive packaging go-to that can handle design, sourcing, and delivery.

Because most suppliers don’t have internal packaging designers, it’s challenging to respond quickly when requirements change. Production builds shift, part designs evolve, and ramp-ups happen in stages. Without the right custom packaging design and supply chain support, these changes can cause costly delays.

The Solution

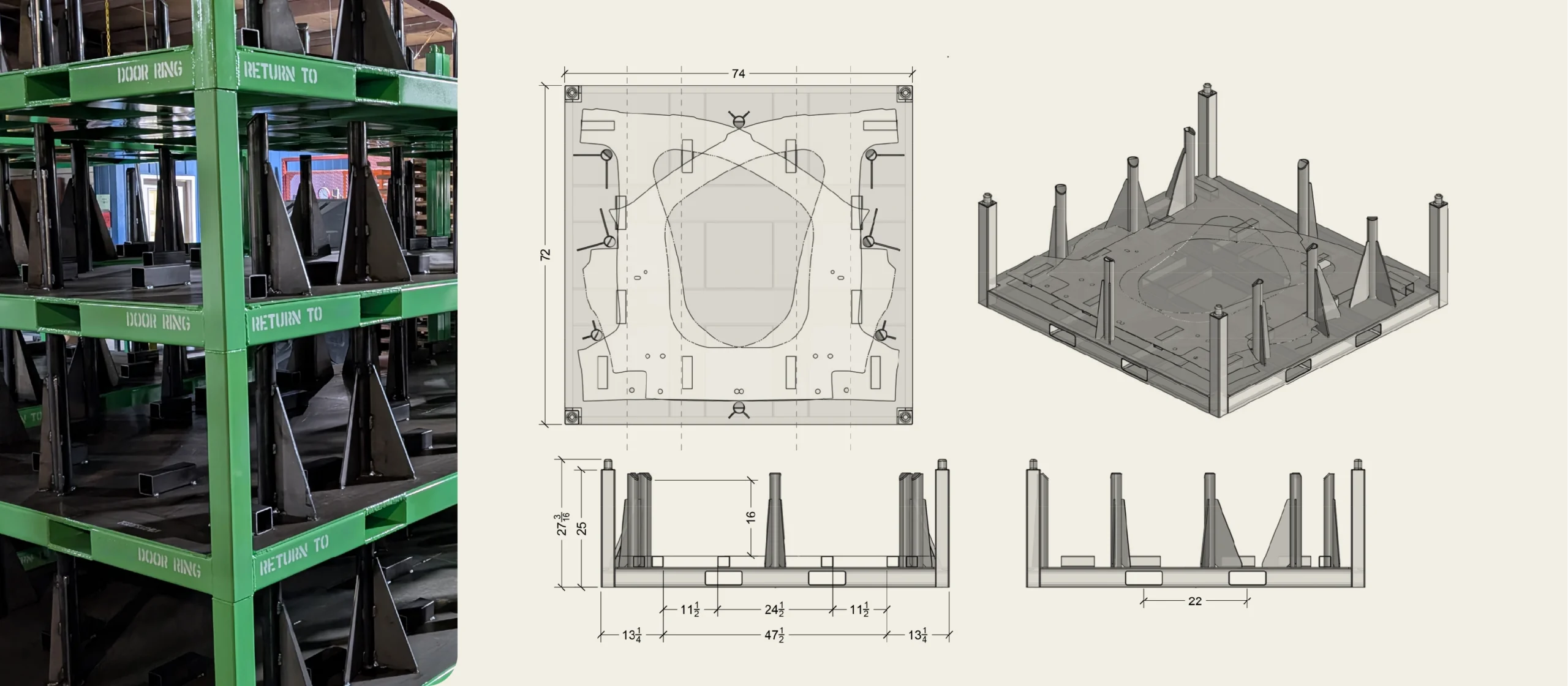

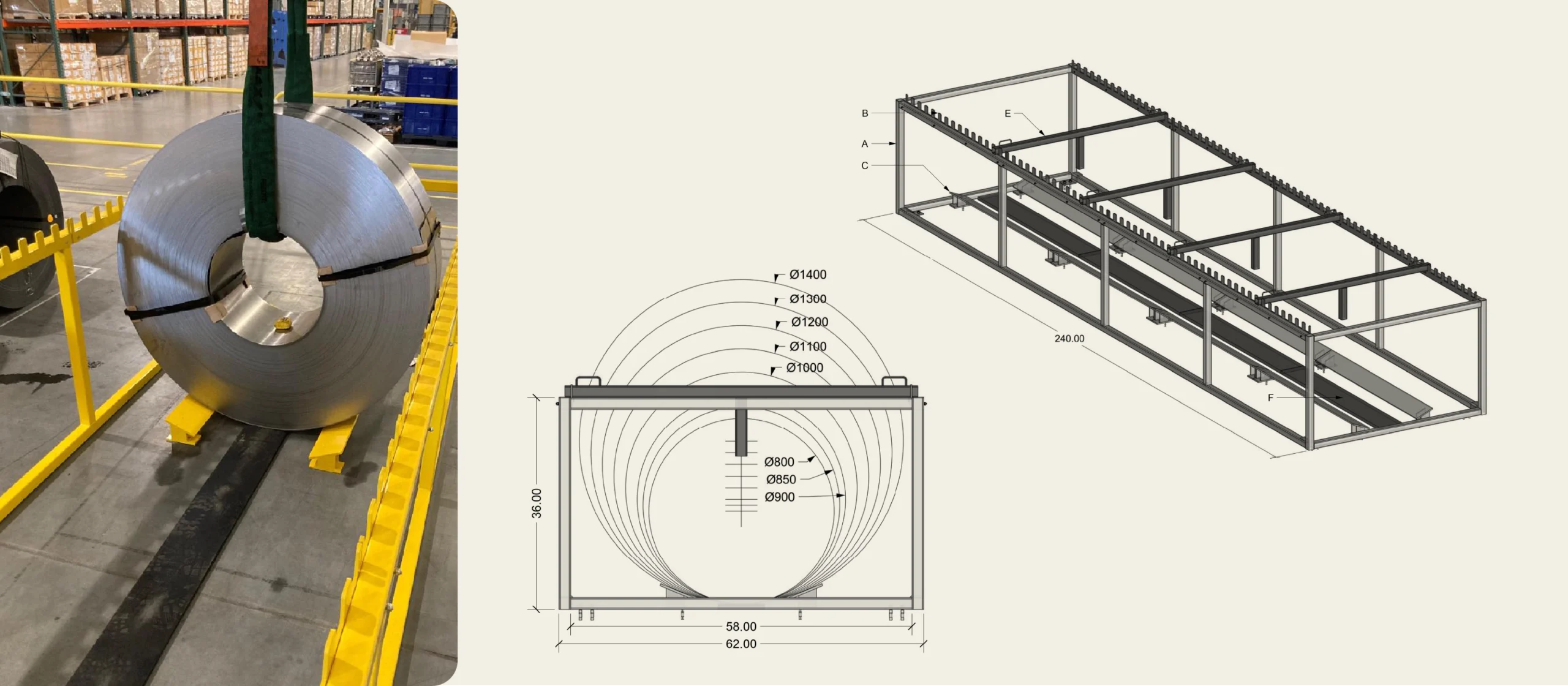

The Tennessee team combines hands-on project management with advanced design capabilities to create packaging systems built for the realities of automotive production. Using customer and plant-level requirements, designs are developed to optimize truck density, operator handling, stackability, and part protection. Detailed 3D renderings, full bills of materials, and precise build drawings ensure a smooth transition from concept to fabrication.

Once designs are approved, the team manages material sourcing, fabrication, and quality control. By working with strategically located fabricators, they can reduce lead times, keep costs in check, and ensure every build meets the demands of plant-floor operations.

The Result

The office has delivered a wide range of programs, including a first-of-its-kind universal door rack that holds both right-hand and left-hand door parts in one unit, saving floor space and streamlining handling. Other projects include custom dunnage racks for work-in-progress stages, high-density bulk racks for raw materials, and expendable service packaging such as corrugated, molded foam, and wood crates for long-distance or aftermarket use.

From unique rack designs to complete lifecycle packaging programs, the Tennessee office delivers solutions that help automotive suppliers reduce damage, save space, and stay on schedule. Every project is built to move, supporting production from the first operation to final assembly with packaging that performs reliably, shift after shift.

Get in touch

Questions? Let’s talk. Our team can help you find what you're looking for.